Know-how

Our products

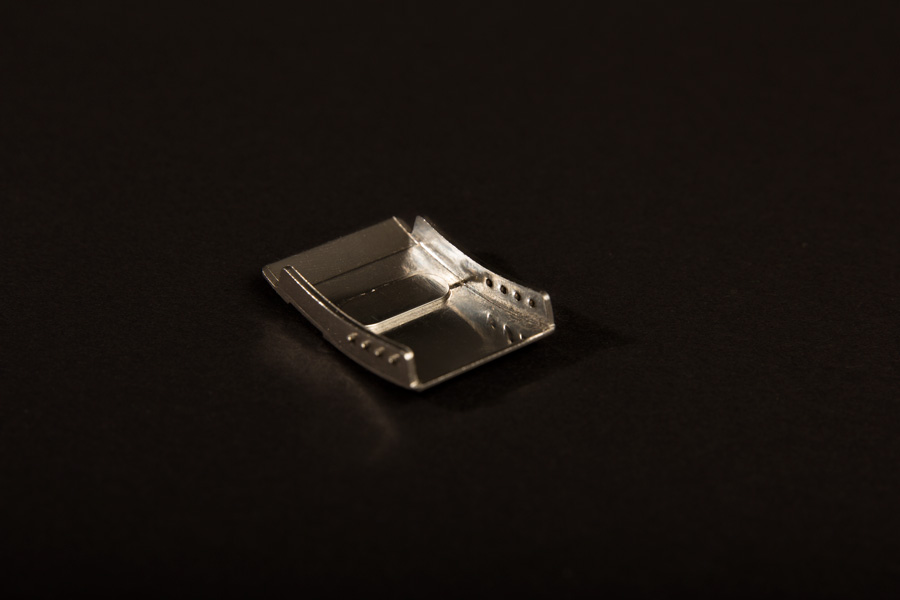

We develop high-end products, focusing on elaborate shapes and high quality surface finishing. We strive to deliver geometries as close as possible to the end piece, allowing our clients to save maximum time in second and finishing operations.

The smoothness of our products’ surfaces allows our client’s finishing operations to be optimised.

Our work ethic is based on precision and mastery of processes in each production stage, from the design of machine tools to the delivery of the stamped part. We thus guarantee our products are of the highest quality regardless of the quantities ordered.

Watchmaking

Most of our business is in watchmaking components. Stainless steel is the material most frequently used but our production range also processes titanium, precious metals (gold, platinum), silver, palladium and tantalum. Our expertise allows us to offer our clients steel or gold productions without a machine tool surcharge.

Half of our “watchmaking” production involves making clasp parts for which we have developed specific techniques to deliver very high tolerance pieces.

Large volumes

Our high production capability means we can produce large volumes of parts while maintaining a high level of quality. We can automate the production of large series while offering very attractive pricing.

Medium and small quantities

Our production set-up may be configured for medium-run steel volumes or for precious metal components in smaller quantities.

Medical

We manufacture products for the dental industry but most of our production revolves around stamping out non-implantable medical instruments. Hardenable stainless steel (1.4021), non-hardenable stainless steel (1.4404) and titanium are the most frequently used materials.

Writing implements

Our expertise gives us a competitive edge in components for writing implements (clips, caps, etc.) which we mainly manufacture in copper-based alloys (nickel silver, Niclafor, etc.). We can deliver hardened and/or polished parts ready for galvanic treatment.

Eyewear

Stamping technology is also used in eyewear components, such as temples, endpieces, bridges or frame fronts. We mainly stamp copper-based alloys (nickel silver, bronze, Niclafor) or steel. For the stamping of temples, we have our own lathe production facility.

Fashion accessories

We also stamp fashion accessories such as parts on belt buckles or clasps used on leather goods. Brass or steel are mainly used for these types of products.